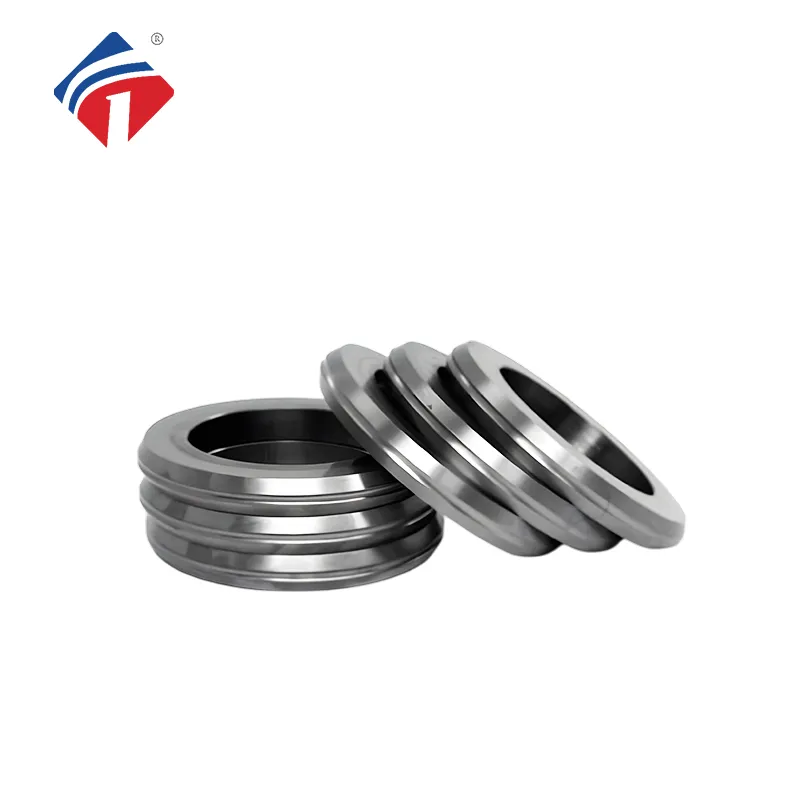

Description

Technical Parameter

1) Main Performance Index

| 牌号 Grade |

化学成分 Chemical Composition |

力学性能 Mechanical Properties |

用途推荐Recommended Application | |||

| WC% | CO% | 密度 Density (g/cm³) |

硬度 Hardness (HRA) |

抗弯强度(B试样) Transverse rupture strength (Sample B) Mpa |

||

| A154 | 85% | 15% | 13.8~14.2 | 83.5 | 2520 | 冷轧螺纹钢 Cold Rolling Ribbed Steel |

| YG15 | 85% | 15% | 13.9~14.2 | 86.5 | 2220 | |

Other Parameter

|

Specification |

O.D (D±0.02) |

I.D (d*) |

Height (H±0.02) |

Space |

0.D (D±0.02) |

I.D (d*) |

Height (H±0.02) |

|

123082015 |

123 |

82 |

15 |

150095015 |

150 |

95 |

15 |

|

125082015 |

125 |

82 |

15 |

150095020 |

150 |

95 |

20 |

|

128082015 |

128 |

82 |

15 |

150096015 |

150 |

96 |

15 |

|

130082015 |

130 |

82 |

15 |

150096020 |

150 |

96 |

20 |

|

130082016 |

130 |

82 |

16 |

180125015 |

180 |

125 |

15 |

|

138080018 |

138 |

80 |

18 |

180125020 |

180 |

125 |

20 |

|

138090018 |

138 |

90 |

18 |

205150015 |

205 |

150 |

15 |

|

145095015 |

145 |

95 |

15 |

205150020 |

205 |

150 |

20 |

|

145095020 |

145 |

95 |

20 |

220140025 |

220 |

140 |

25 |

|

147095015 |

147 |

95 |

15 |

|

|

|

|

Note

1. The table specifications are recommended guidelines; however, we also manufacture roll rings to customer-provided drawings.

2. Roll ring grooves can be designed and manufactured to comply with the GB13788-2000 standard or customized according to customer requirements, including specific marking.

3. We supply compatible tool steel systems to support customer mill and rolling process modifications.

2) Application Requirements

a. Compact/Knock-on roll rings are strictly prohibited.

b. During assembly of the roll ring unit, maintain bearing clearance on the tighter side.

c. Rotational accuracy (radial and axial runout) of the fully assembled unit must be maintained within ±0.05 mm.

d. The interface between the roll rings and the assembly components must be a transitional/interference fit, with all components securely fastened.

e. Roll rings must not be cooled using water or oil-water emulsions.

f. Internal cooling system pipe joints must be leak-proof. We strongly recommend avoiding internal cooling systems altogether.

INQUIRY

Related product categories

- supplier of roll rings for steel mills

- cemented carbide roll rings for seamless tube mills

- ISO-certified carbide roll rings for wire rod mills

- carbide roll rings Brazil for sale

- long-lasting carbide roll rings for alloy steel rolling

- bulk purchase of roll rings for roll rings

- china cemented carbide unground rod

- carbide rolls Brazil

- cemented tungsten carbide inserts for engraving

- cnc end mill starter set

- end mill cutter

- china cnc ball end mill

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de