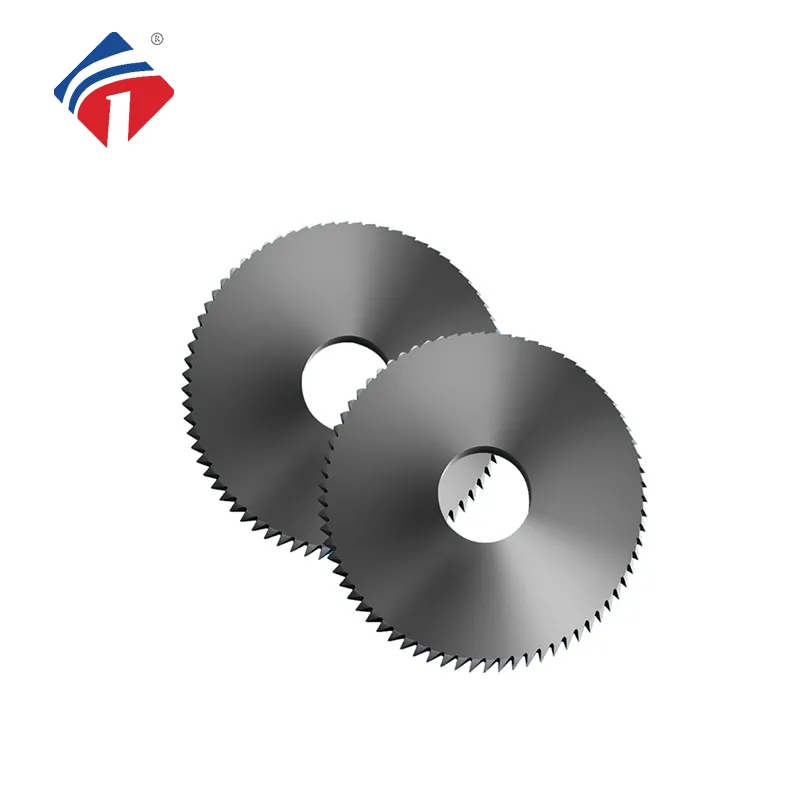

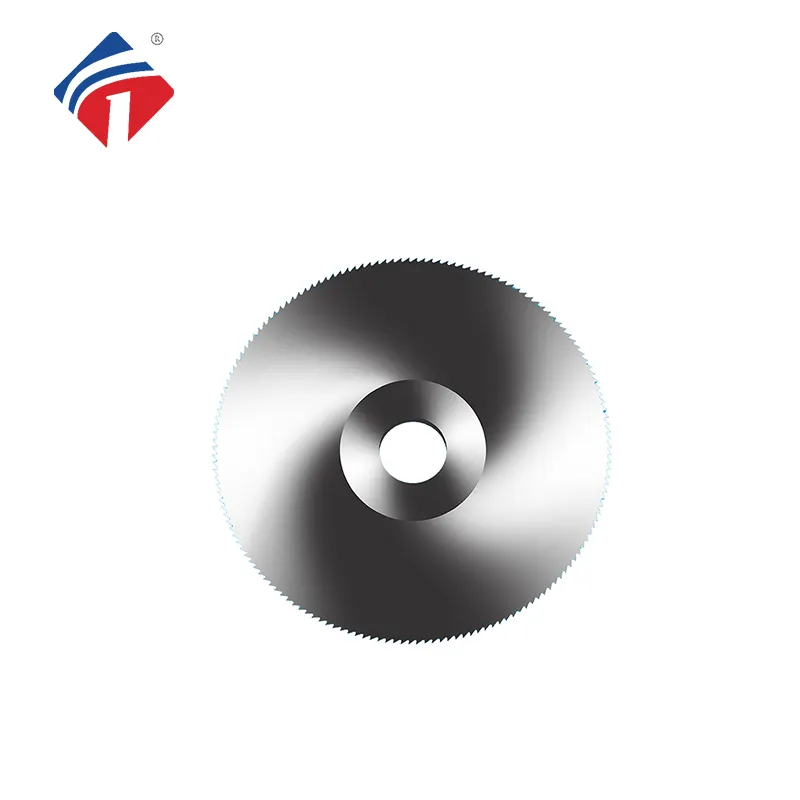

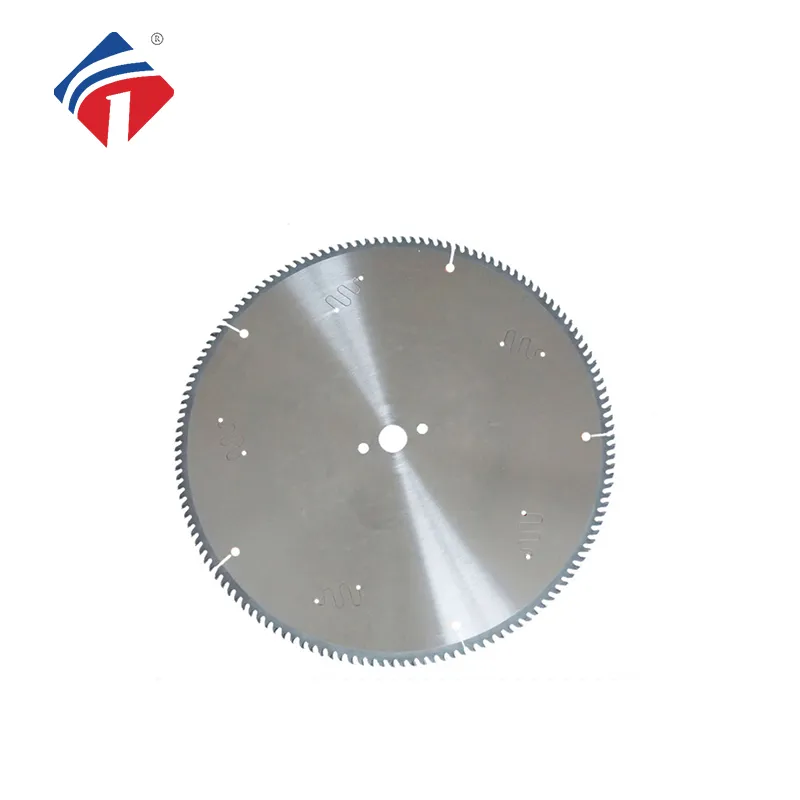

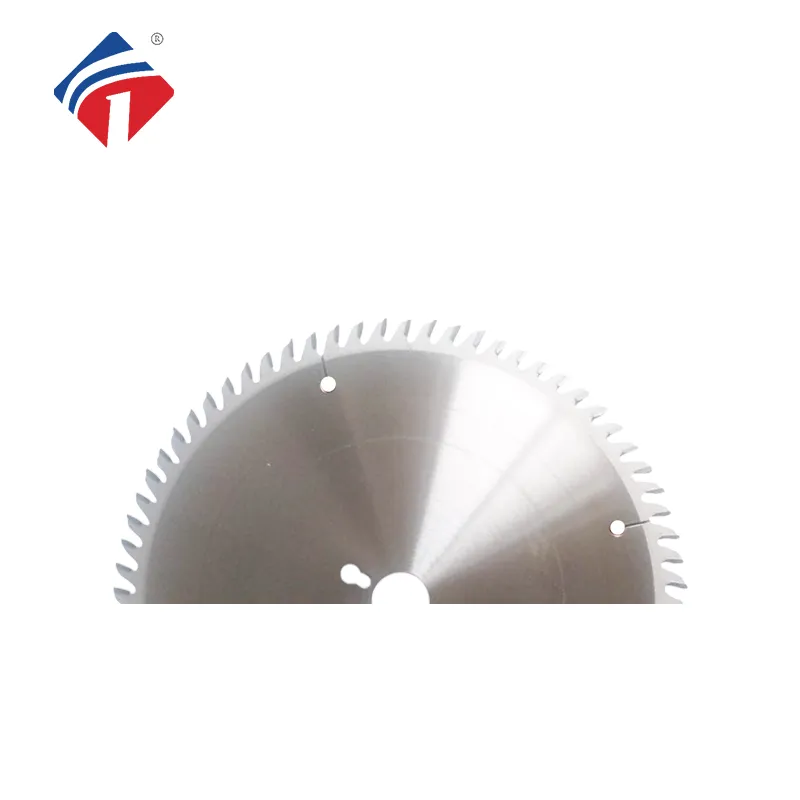

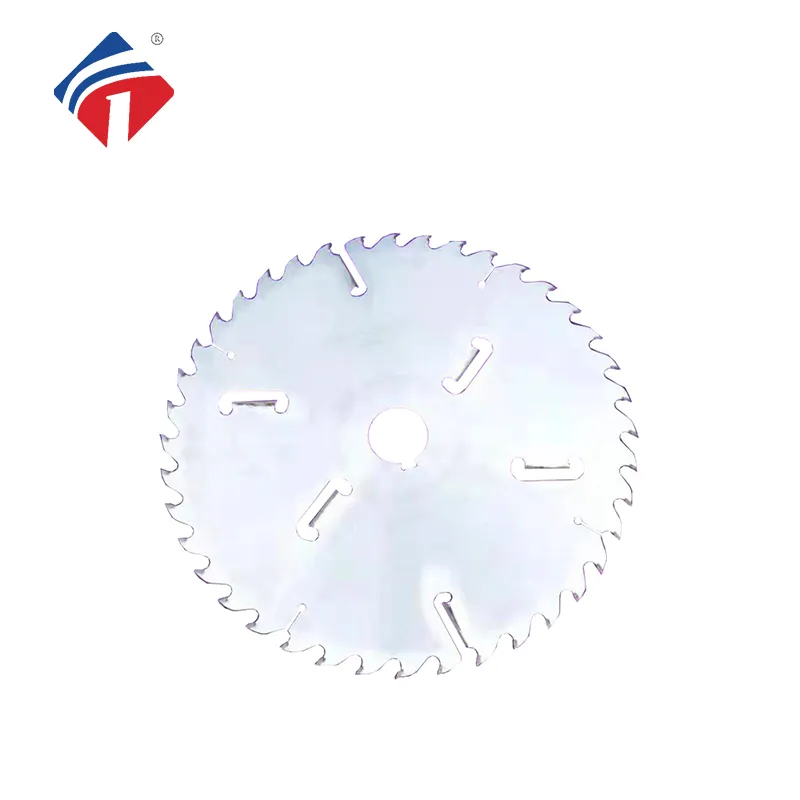

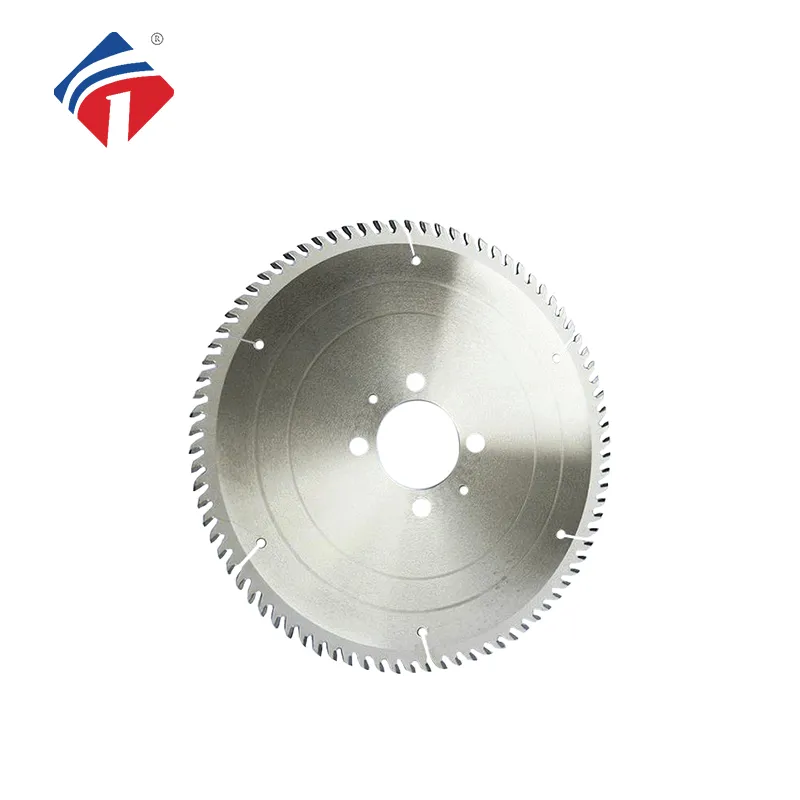

Solid Carbide Saw Blade with Teeth

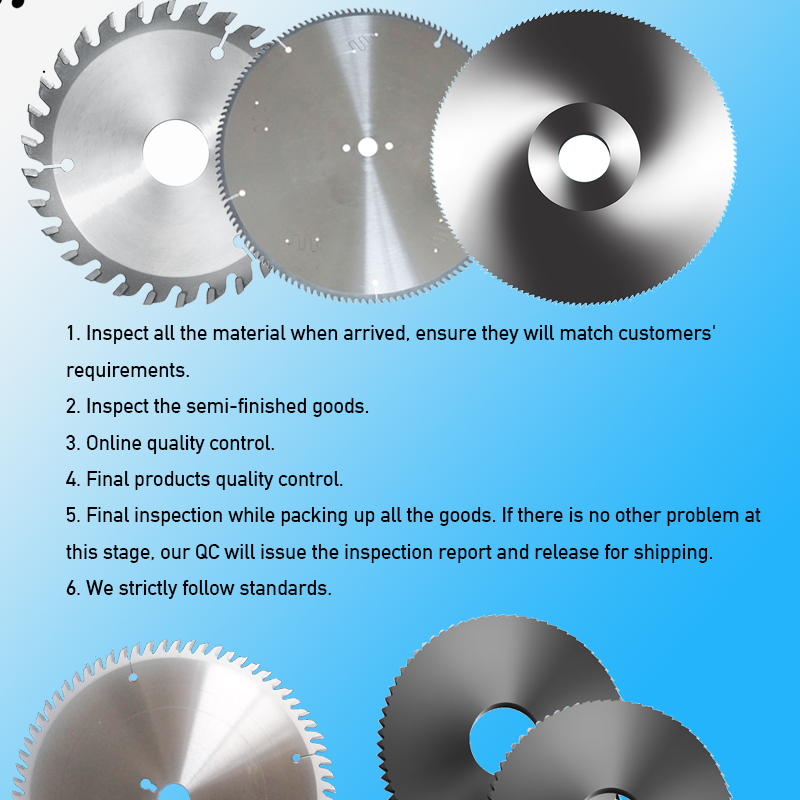

A solid carbide saw blade with teeth is an advanced cutting tool designed for high-performance applications where precision, durability, and cutting efficiency are critical. Made from solid carbide, these saw blades offer exceptional hardness and wear resistance, making them ideal for cutting through tough materials such as metals, composites, and hard alloys.

The teeth of the saw blade are designed to provide optimal cutting efficiency, ensuring smooth, accurate cuts while minimizing wear on the tool. The unique composition of solid carbide enables these blades to maintain sharpness and cutting precision over extended use, reducing downtime and the need for frequent tool replacements.

With applications ranging from industrial cutting to precision machining, solid carbide saw blades with teeth are the preferred choice for professionals looking to achieve high-quality, cost-effective results in challenging cutting conditions.

Description

The sizes of carbide saw blade with teeth:

|

Type |

O.D(D) mm |

I.D(d) mm |

Thickness(s) mm |

Number of teeth |

|

TY0803-S-A(B)Z |

8 |

3 |

0.2~2 |

20, 24, 32 |

|

TY1205-S-A(B)Z |

12 |

5 |

0.2~2 |

20, 24, 32, 40 |

|

TY1605-S-A(B)Z |

16 |

5 |

0.2~2 |

20, 24, 32, 40, 48 |

|

TY2005-S-A(B)Z |

20 |

5 |

0.2~2 |

24, 32, 48 64 |

|

TY2508-S-A(B)Z |

25 |

8 |

0.2~2 |

24, 32, 48, 64, 80 |

|

TY3208-S-A(B)Z |

32 |

8 |

0.2~3 |

40, 48, 64, 80 |

|

TY4008-S-A(B)Z |

40 |

8 |

0.2~3 |

40, 64, 80, 100 |

|

TY4010-S-A(B)Z |

40 |

10 |

0.2~3 |

40, 64, 80, 100 |

|

TY5012-S-A(B)Z |

50 |

12.7 |

0.2~4 |

40, 64, 80, 100 |

|

TY5013-S-A(B)Z |

50 |

13 |

0.2~4 |

40, 64, 80, 100 |

|

TY6012-S-A(B)Z |

60 |

12.7 |

0.2~5 |

40, 64, 80, 100 |

|

TY6016-S-A(B)Z |

60 |

16 |

0.2~5 |

40, 64, 80, 100 |

|

TY6316-S-A(B)Z |

63 |

16 |

0.2~5 |

40, 64, 80, 100 |

|

TY7012-S-A(B)Z |

70 |

12.7 |

0.2~5 |

48, 64, 72, 90, 100 |

|

TY7022-S-A(B)Z |

70 |

22 |

0.2~5 |

48, 64, 72, 90, 100 |

|

TY7025-S-A(B)Z |

70 |

25.4 |

0.2~5 |

48, 64, 72, 90, 100 |

|

TY7522-S-A(B)Z |

75 |

22 |

0.2~5 |

64, 72, 90, 100 |

|

TY7525-S-A(B)Z |

75 |

25.4 |

0.2~5 |

64, 72, 90, 100 |

|

TY8022-S-A(B)Z |

80 |

22 |

0.2~5 |

64, 72, 100, 120 |

|

TY8025-S-A(B)Z |

80 |

25.4 |

0.2~5 |

64, 72, 100, 120 |

|

TY9022-S-A(B)Z |

90 |

22 |

0.2~5 |

72, 90, 100, 120 |

|

TY9025-S-A(B)Z |

90 |

25.4 |

0.2~5 |

72, 90, 100, 120 |

|

TY10022-S-A(B)Z |

100 |

22 |

0.2~5 |

90, 100, 120, 160 |

|

TY10025-S-A(B)Z |

100 |

25.4 |

0.2~5 |

90, 100, 120, 160 |

|

TY10032-S-A(B)Z |

100 |

32 |

0.2~5 |

90, 100, 120, 160 |

|

TY11022-S-A(B)Z |

110 |

22 |

0.2~5 |

100, 120,140, 160 |

|

TY11025-S-A(B)Z |

110 |

25.4 |

0.2~5 |

100, 120,140, 160 |

|

TY11032-S-A(B)Z |

110 |

32 |

0.2~5 |

100, 120,140, 160 |

Solid carbide saw blades with teeth are suitable for cutting all types of metals.

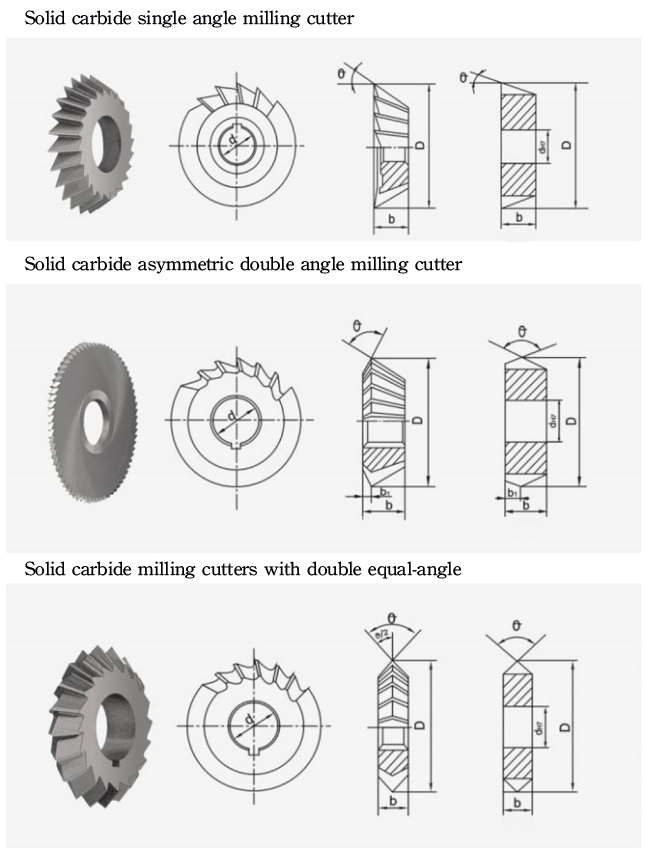

Carbide Milling cutters with single angle

INQUIRY

Related product categories

- top suppliers of tungsten carbide roll rings for steel mills

- supplier of roll rings for mance rolls

- custom-manufactured roll rings for high-temperature applications

- improve rolling mill efficiency for steel mills

- reduce downtime with carbide rolls for high-speed wire rod mills

- China long-lasting carbide roll rings

- carbide roller rings Iran

- china cemented carbide bars for engraving

- cemented carbide roll rings Israel

- china drill mill bit

- tungsten carbide rolling ring

- cemented carbide roll rings

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de